Interests

Production of fuels and chemicals from sustainable sources, Synthesis of inorganic materials with an eye on applications in aerospace, optics and chemical feedstock. Examination of the kinetics and mechanism of solid-solid mechanochemical reactions. Development of Forensic analytical methods for the presumptive identification of substances of abuse.

Sustainable Fuels and Chemicals

Mechanocatalytic Production of Chemicals from Biomass

Mechanocatalytic Production of Chemicals from Biomass

U.S. Patent 8,062,428 Licensed, Carbolosic Corporation

The production of biorenewable fuels is currently a topic of intense investigation. However, fuels are commodity chemicals that must be made as cheaply as possible and in large quantities to realize profit from them. Petroleum remains a relatively inexpensive commodity and biofuels face a significant pricing disadvantage. In order to lower the costs associated with biofuels, the components of woody biomass (cellulose, hemicellulose, and lignin) and algae (polysaccharides and protein) must be examined with an eye toward converting them to simple molecules that can be

Work in my laboratory has shown that solids can be effective in mechanically induced catalysis and that layered structures exhibit the best catalytic activity. We have observed products due to catalytic hydrolytic depolymerization, retro-aldol reactions, dehydration, oxidation, and hydrogenation. Product composition is strongly affected by the chemical and physical properties of the catalyst. Previous work has shown that layered acidic aluminosilicates like kaolin can be used to depolymerize cellulose. We have also found that the same silicates can be used to induce dehydration in sugars and alcohols. The work is now focused on mechanocatalysts for lignin depolymerization and value added chemicals from saccharides.

Heterogeneous Metal-Free Hydrogenation Over Defect Laden SolidsProvisional Patent filed, Funded, The United States Air Force Research Laboratory

Heterogeneous Metal-Free Hydrogenation Over Defect Laden SolidsProvisional Patent filed, Funded, The United States Air Force Research Laboratory

Collaboration with Prof. Talat Rahman in the Univerisy of Central Florida’s Physics Department

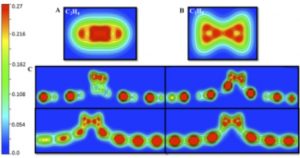

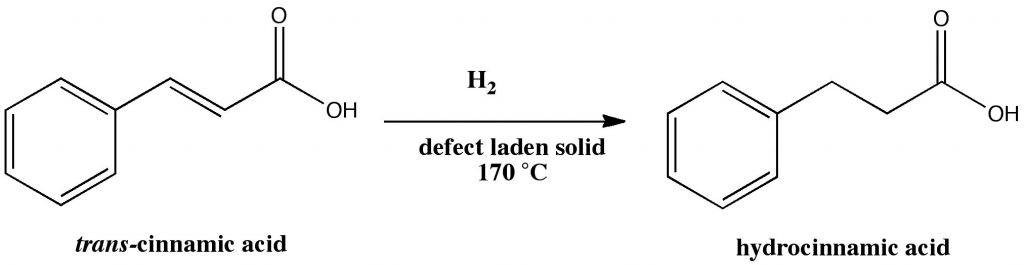

Metal-free heterogeneous hydrogenation catalysts based on frustrated Lewis pairs would significantly reduce the health, environmental and economic concerns currently associated with metal-based catalysts. Typically, hydrogenation is carried out using transition metal catalysts. These metals exhibit useful catalytic properties unseen in main group elements such as carbon, nitrogen, and phosphorus. Catalytic hydrogenation has been exploited in the preparation of foods, purification of fine chemicals, and in the processing of exhaust gases. However, there is growing concern over the use of these metals. The Blair lab has developed the first metal-free heterogeneous hydrogenation catalyst. Catalytic hydrogenation was observed in the conversion of trans-cinnamic acid to hydrocinnamic acid, over defect-laden structures in a reactor designed to maximize these defects. DFT calculations show that the alkene bond is weakened over these structures.

Inorganic Materials

Mechanochemical syntheses represent a scalable approach to the preparation of inorganic materials. We can perform reactions from 200 mg to 500 g.

Improved Production of Edge Functionalized Graphene

Improved Production of Edge Functionalized Graphene

Funded, Garmor Incorporated

Collaboration with Prof. Masa Ishigami in the Univerisy of Central Florida’s Physics Department

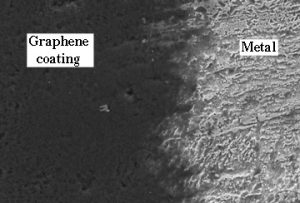

Oxidized graphite can be rapidly prepared by mechanochemical means. Grinding urea hydrogen peroxide adduct with graphite and no solvent produces a product with an oxygen content of 5-15 wt%. The by-products of this synthesis are urea and water. The oxidized graphite produced by this method is hydrophilic and easily suspended in water; this allows for convenient processing of films with resistivities between 50 Ω/cm2 and 8 kΩ/cm2. This material has properties significantly different from traditionally synthesized graphite oxide. We have implemented scalable milling technology to produce up to 50 grams at a time. From our measurements we have inferred that the graphite has been fully oxidized to –COOH groups along the edges of individual graphene sheets. This syntheses represents the first real improvement in the syntheses for oxidized graphite in over 50 years.

Refractory Nanoelectroceramic Composites for Enhanced Radioisotope Thermoelectric Power Generation in Long-duration Space Flight

Refractory Nanoelectroceramic Composites for Enhanced Radioisotope Thermoelectric Power Generation in Long-duration Space Flight

Funded, Florida Space Institute

Collaboration with Prof. Ghatu Subhash in the University of Florida’s Department of Mechanical and Aerospace Engineering

Thermoelectric power generation is a robust method for producing the power needed for space applications. Currently, all spacecrafts that have travelled past Mars utilize radioisotope thermoelectric generators (RTGs). In fact, the Mars Science Laboratory uses an RTG for its main power source. Thermoelectric power generation has advantages over solar generation in that it can provide consistent power at distances from the Sun where the solar flux is low and allowing planetary missions to gather data through nights and poor weather such as dust storms on Mars

The current material of choice for RTG mission is Si80Ge20, it has a high operational temperature (1000 C) and is robust enough to survive the rigors of launch and deployment. However, this material does not efficiently convert heat into power. Current RTG modules produce about 200 watts of power. Increased exploration of the solar system will demand higher power modules. An effort has been made to replace RTG with Stirling-type power modules. Although successful for terrestrial applications, there are concerns about the long time usability of a system with moving parts. In comparison, the RTGs on the Voyager spacecraft are still producing enough power (267.5 and 268.7 watts) for the instrumentation to produce and broadcast data.

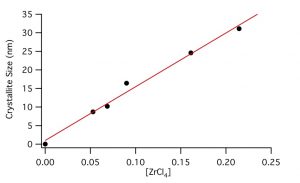

Realizing the current limitation that silicon-germanium based RTGs cannot efficiently produce large amounts of power required for long duration flights, we are focussing on producing filled-skutterudites, Zintl phases, and lanthanum telluride materials with nanoparticles of refractory conductors. These compounds form the basis for thermoelectric modules that operate near room temperature. We are synthesizing powders of the matrix materials using pure elements and mechanochemical synthesis and mechanically assisted solid-state metathesis for the nanoparticles. Dr. Ghatu Subhash at the University of Florida is consolidating these powders using a rapid consolidation process called spark plasma sintering (SPS) and conducting mechanical tests to evaluate their integrity.

Forensic Science

Transition Metal Cluster Compounds for the Fluorescent Identification and Trace Detection of Substances of Abuse Funded, The National Institute of Justice

Transition Metal Cluster Compounds for the Fluorescent Identification and Trace Detection of Substances of Abuse Funded, The National Institute of Justice

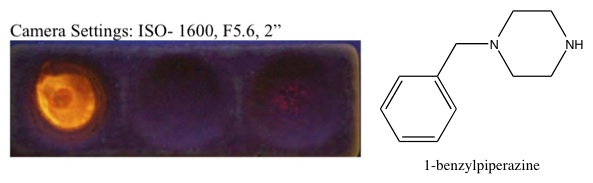

Sensitive, rapid, high-sensitivity and low cost methods for detecting substances of abuse are being developed. This work focuses on developing fluorescent indicators for substances of abuse with enhanced specificities. These new fluorescent indicators are based on d10 metal complexes and allow greater detection sensitivity and flexibility. The indicators are shelf-stable, low-cost and the complexes formed can be stored for long periods of time without loss of fluorescence. The fluorescence observed in these complexes is due to the nature of the metal and metal-analyte bonds present in the complex. This is a well understood phenomena and will stand up to Daubert challenges.

By coupling new sources, fluorescent indicators, and digitizing systems, it will be possible to positively identify compounds rapidly in the field and in the lab. Ultimately, this approach could be implemented in a small handheld system that will allow assessment of multiple indicators in the field.

X-ray Diffraction

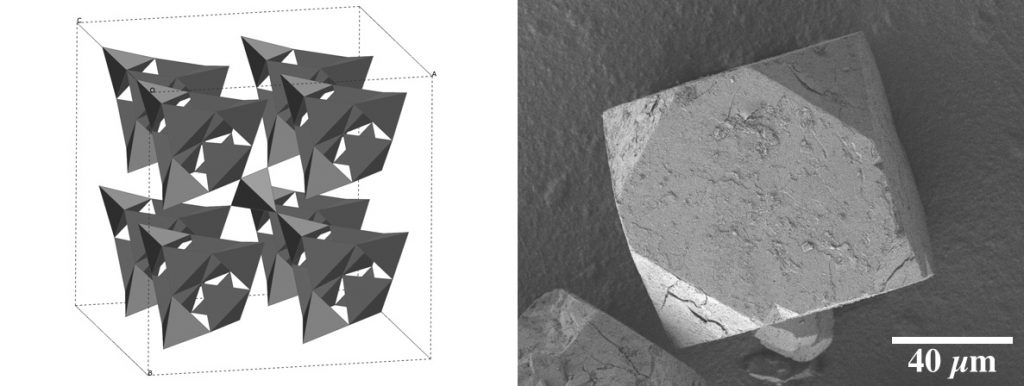

Powder and single crystal X-ray diffraction are analytical methods that are very important to our group. Below is our recently reported structure of cubic CaSiN2.

The identification of new compounds and phases of materials generated from solid-solid reactions are best identified by powder X-ray diffraction (XRD). We are also experienced in crystallite size and strain analysis of our materials through powder XRD. Our research focuses on new methods of the rapid synthesis of inorganic materials, examination of the mechanism of compound formation, and identification using X-ray diffraction.