BY| Kelly Lai and Brad Hoover

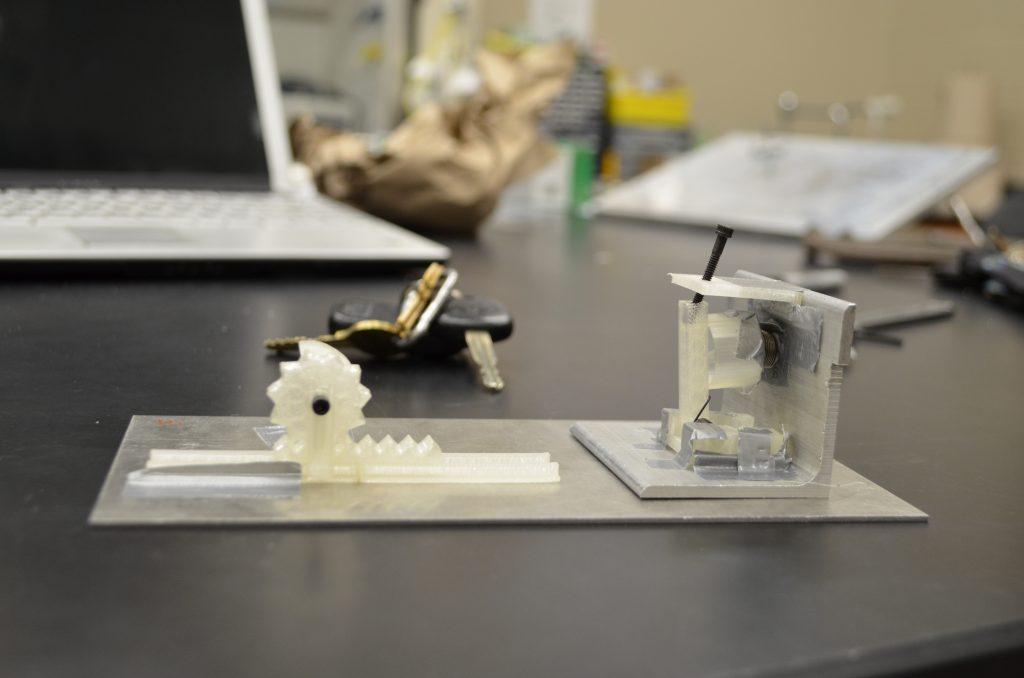

The electrical prototype will utilize muscle wire, which is a shape-memory alloy, and various torsion springs to achieve the requested results. First, the launching bar, that keeps the spring and launching cup compressed until it is ready for launch is held in a vertical position with a 180° torsion spring and a spring plunger. When zero-gravity is detected, the user will activate the first round of muscle wires. This first round will pull the spring plunger back, thus releasing the launching bar to revert back to a horizontal position and allowing the spring to launch the launching object.

Once the object has made its way through the cloud of regolith, it will approach the capture mechanism of the tube. The capture mechanism will use a gear and torsion spring system. The capture hemisphere will have a natural tendency to stay in the “closed” position. The torsion spring will ensure that it stays in a closed position, the open side of the hemisphere facing the back wall. However, the hemisphere will be turned to the open position and held open with a spring plunger. Once the launching object reaches the capture hemisphere, the user will then activate the second round of muscle wires. This will pull the spring plunger out of its locking position and allow the hemisphere to revert back to its primary position of “closed.”

This electrical prototype compared to the mechanical prototype provides a more reliable way to release and capture the launching object. It eliminates a majority of human error, as well as eliminates numerous moving parts. More moving parts increases the amount of error the payload can have.

A minor flaw of the electrical prototype is the time it takes for the muscle wire to contract.

The purely mechanical version of the CATE that I am designing has a few benefits that make it an attractive option. However there are aspects to Kelly’s electromechanical design that could also make it a better choice.

One of the key benefits to the mechanical prototype is that it will involve no electrical components, leaving less room for something to go wrong or malfunction. Our lab has encountered electrical issues in the past with other experiments so the possibility of electrical components failing is fresh in our minds. Another important aspect is the cost. A purely mechanical design will be less complex and will likely be the cheaper and more easily manufactured option.

One of the flaws of the mechanical version is that it will require more human interaction during its use. A tended experiment leaves room for human error and will require some trial and error during the first few parabolas to get it just right.